Factory Outlets Conveyor Wear Plate Steel - WD1800 Wear Plates – Wodon

Factory Outlets Conveyor Wear Plate Steel - WD1800 Wear Plates – Wodon Detail:

WD1800 series

Abrasion Resistant Chromium Carbide Overlay

WD1800 is complex carbide composite cladding fusion bonded to a mild steel backing plate. WD1800 wear plate is suitable for application involving high abrasion at elevated temperature up to 900 ℃.

● WD1800 series:

Complex carbide wear plates; Suited for applications involving high abrasion at elevated temperatures up to 900 degree.

|

Chemicals |

Hardness |

Sheet Size |

Base Metal |

|

C – Cr – Nb – Mo – Ni – W – V – Fe |

HRC 58-63 |

1400*3500/2100*3500 |

Q235/Q345. etc |

| Chemical Composition(%) |

C |

Cr |

Mn |

Si |

Mo+Ni+V+Nb+W |

Fe |

|

4.0-7.0 |

25.0-40.0 |

- |

- |

4.0 -14.0 |

Bal. |

|

| Hardness |

HRC 58-65 |

|||||

| Standard Thickness(mm) |

6+6; 8+6; 8+8; 10+10; 12+12; 12+17; 14+26; 12+32; etc (overlay thickness up to 50mm) |

|||||

| Standard Sheet Size(mm) |

1400*3500; 2100*3500 (Customized size available) |

|||||

| ASTM G65 Procedure A |

0.09 - 0.16g |

|||||

| Operating Temperature |

<900℃ |

|||||

| Base Metal Material |

Q235B, Q345B; A36; S235JR and structural steels |

|||||

| Main Industry |

Mining, glass industry, cement plant, steel mill, power plant, bulk material handling, etc |

|||||

| Fabrication |

Plasma cutting, Gouging, Countersunk, stud bolt, Bending |

|||||

Note:Carbon and Chromium content varies in different plate.

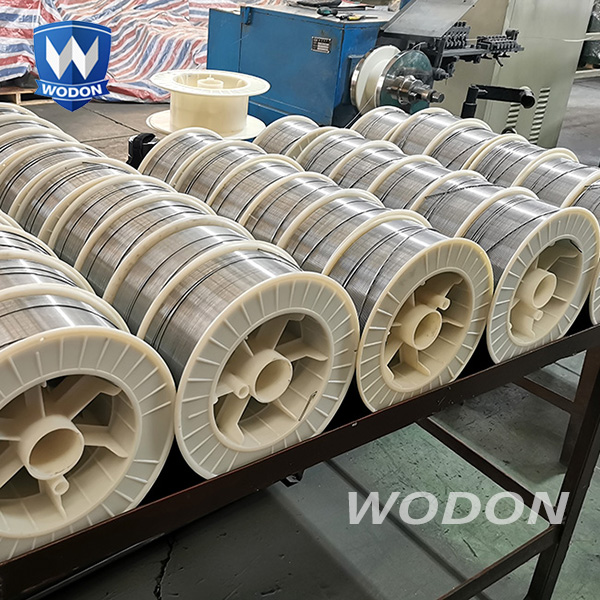

Product detail pictures:

Related Product Guide:

Our crew through skilled training. Skilled skilled knowledge, strong sense of company, to meet the company wants of customers for Factory Outlets Conveyor Wear Plate Steel - WD1800 Wear Plates – Wodon , The product will supply to all over the world, such as: America, Las Vegas, Porto, Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us. Thank you - Your support continuously inspires us.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.