-

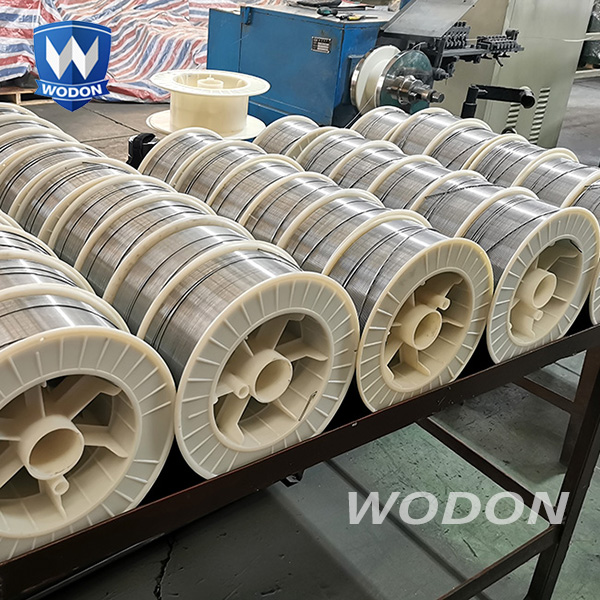

2.8/3.2mm Flux Core Welding Wire for Hardfacing Wear Plate

2.8/3.2mm Flux Core Welding Wire for Hardfacing Wear Plate -

Hardfacing Chromium Carbide Wear Resistant Flux Core Welding Wire

Hardfacing Chromium Carbide Wear Resistant Flux Core Welding Wire -

Wear Plate Welding Wire

Wear Plate Welding Wire -

Roller Repairing Hardfacing Wires

Roller Repairing Hardfacing Wires -

Gas shielded Hardfacing Wires

Gas shielded Hardfacing Wires

Wear Plate Welding Wire

| Model | Spec.(mm) | HRC | Main Ingredient | Applications |

| HD161 | 2.8、3.2 | 58~65 | C、Cr、Mn、Si | For hardfacing single layer wear plate |

| HD161+ | 2.8、3.2 | 58~65 | C、Cr、Mn、Si | For hardfacing single layer wear plate |

| HD181 | 2.8、3.2 | 58~65 | C、Cr、Mn、Si | For hardfacing ultrathin wear plate |

| HD30 | 2.8、3.2 | 55~63 | C、Cr、Mn、Si | For hardfacing multiple wear plate |

Gas Shielding Welding Wire

|

Model |

Spec.(mm) |

HRC |

Main Ingredient |

Applications |

| D114 | 1.6 | 50~55 | C、Cr、Mn | For hardfacing hammer head,hammer plate and other high impact parts |

| D172 | 1.2、1.6 | ≥40 | C、Cr、Mo | For hardfacing bucket gear,mining machinery and others |

| D212 | 1.2、1.6 | ≥45 | C、Cr、Mo | For hardfacing the surface of wear parts, such as gear,digger,mining machinery etc |

| D256 | 1.6 | HB≥170 | C、Mn | For hardfacing high manganese rail,bulldozer and other wear parts under impact |

| D313 | 1.6 | 45~50 | C、Cr | For hardfacing continuous casting roller |

| D322 | 1.6 | 55~63 | C、W、Mo | For repairing die and toughening tool and mechanical parts with high wear performance |

| D405 | 1.6 | 53~60 | C、Cr、Mo、W、V | For hardfacing hot rolling roll |

| D430 | 1.6 | 35~40 | C、Cr | For hardfacing general corrosion resistant parts |

| D502Mo | 1.6 | 35~45 | C、Cr、Mo | For hardfacing valve |

| D518 | 1.6 | 40~50 | C、Cr、Mo、Ni | For hardfacing continuous casting roller |

| D688 | 1.2、1.6 | 50~58 | C、Cr | For hardfacing heavy wear parts |

| D788 | 1.2、1.6 | 50~60 | C、Cr | For hardfacing heavy wear parts |

| D788A | 1.2、1.6 | 50~60 | C、Cr | For hardfacing heavy wear part,single layer welding only |

| D888 | 1.2、1.6 | 58~65 | C、Cr | For hardfacing heavy wear parts |

| D995 | 1.6 | 58~65 | C、Cr、Nb、W、V | For hardfacing heat resistant wear parts |

| D688Welding rod | 4.0 | 50~62 | C、Cr | For welding by severe abrasive wear parts |

Vertical Cement Mill Welding Wire

| Model | Spec.(mm) | HRC | Main Ingredient | Applications |

| HB100 | 2.8、3.2 | 58~63 | C、Cr、Mo | For repairing Coal grinding mill,Grinding disc,Cement vertical mill |

| HB100L+ | 2.8、3.2 | 58~63 | C、Cr、Mo | |

| HB100+ | 2.8、3.2 | 58~63 | C、Cr、Mo | |

| HB350 | 2.8、3.2 | 55~63 | C、Cr、Mo、Nb | |

| HB650 | 2.8、3.2 | 58~63 | C、Cr、Mo、Nb |

Cement Squeeze Roller Welding Wire

| Model | Spec.(mm) | HRC | Main Ingredient | Applications |

| D01 | 2.8 | ~ | C、Cr、Mo | For base layer |

| D100Mo | 2.8 | 55~63 | C、Cr、Mo | For buffer layer |

| D650 | 2.8 | 55~63 | C、Cr、Mo | For pattern layer |

Steel Mill Roller Welding Wire

|

Model |

Spec.(mm) |

HRC |

Main Ingredient |

Applications |

| D430 | 2.4、3.2 | 35~45 | C、Cr | For hardfacing common corrosive component |

| 320H | 3.2、4.0 | ~ | C、Cr | For hardfacing continuous casting roller |

| 224 | 3.2、4.0 | 45~55 | C、Cr、Mo、W | For hardfacing hot rolled billet roller |

| 224B | 3.2、4.0 | 50~60 | C、Cr、Mo、W | For hardfacing hot rolled billet roller |

| 414N | 3.2、4.0 | 40~50 | C、Cr、Mo | For hardfacing continuous casting roller |

| 414-O | 3.2、4.0 | 40~50 | C、Cr、Mo | For hardfacing continuous casting roller |