High Quality Wear Plate Welding Wire - Roller Repairing Hardfacing Wires – Wodon

High Quality Wear Plate Welding Wire - Roller Repairing Hardfacing Wires – Wodon Detail:

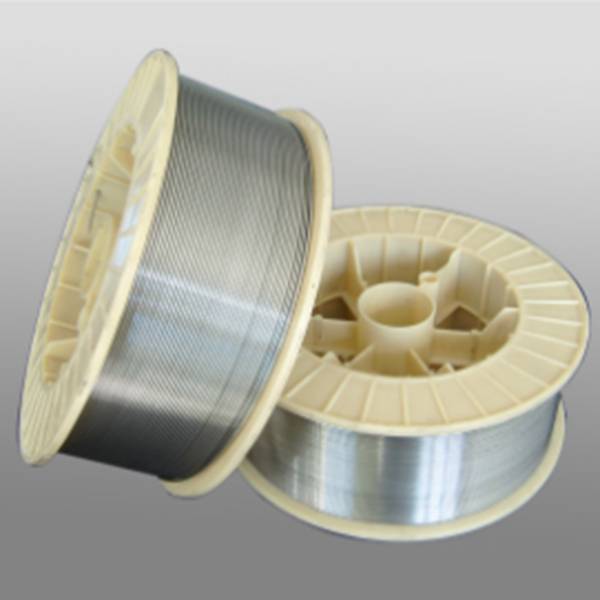

Vertical Roller Hardfacing welding wire

| Application | Model | hardness | Spec (mm) | Main Ingredients |

| Suitable for repairing coal grinding mill, grinding disc, cement vertical mill, etc. | HB100 | 58-63 | 2.8, 3.2 | C, Cr, Mo |

| HB100L+ | 58-63 | 2.8, 3.2 | C, Cr, Mo | |

| HB100+ | 58-63 | 2.8, 3.2 | C, Cr, Mo | |

| HB350 | 58-63 | 2.8, 3.2 | C, Cr, Mo, Nb | |

| HB650 | 58-63 | 2.8, 3.2 | C, Cr, Mo, Nb |

Squeeze Roller Hardfacing welding wire

| Application | Model | Diameter [mm] | Hardness [HRC] | Main Ingredient |

| Suitable for base layer | HB-JYG1# | 2.8 | - | C, Cr, Mo |

| Suitable for buffer layer | HB-JYG2# | 2.8 | 55-63 | C, Cr, Mo |

| Suitable for pattern layer | HB-JYG3# | 2.8 | 55-63 | C, Cr, Mo |

Product detail pictures:

Related Product Guide:

Our products are greatly acknowledged and reliable by users and may fulfill repeatedly shifting financial and social wants for High Quality Wear Plate Welding Wire - Roller Repairing Hardfacing Wires – Wodon , The product will supply to all over the world, such as: Brisbane, Argentina, Montpellier, As the world economic integration bringing challenges and opportunities to the xxx industry, our company , by carrying on our teamwork, quality first, innovation and mutual benefit, are confident enough to provide our clients sincerely with qualified products, competitive price and great service, and to build a brighter future under the spirit of higher, faster, stronger with our friends together by carrying on our discipline.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.

Write your message here and send it to us