-

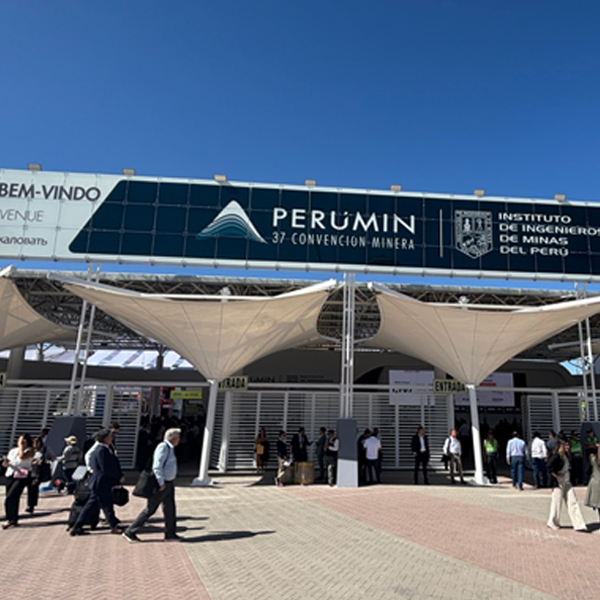

Wodon at PERUMIN 37 – Shaping the Future of Mining with Wear-Resistant Solutions

Wodon at PERUMIN 37 – Shaping the Future of Mining with Wear-Resistant Solutions Wodon is excited to participate in PERUMIN 37 – Mining Convention 2025 in Arequipa, Peru, from September 22–26, 2025. As a leading provider of wear-resistant materials and customized fabrication solutions, we ...Read more -

Why Chromium Carbide Overlay Plates Outperform Conventional Wear Steel

Why Chromium Carbide Overlay Plates Outperform Conventional Wear Steel Abrasive wear caused by hard mineral particles is one of the most severe degradation mechanisms in heavy industries such as mining, cement, power generation, and metallurgy. Once structural components such as chutes, h...Read more -

Base Plate Selection Guide for Chromium Carbide Overlay Wear Plate: Q235 vs. Q355

Base Plate Selection Guide for Chromium Carbide Overlay Wear Plate: Q235 vs. Q355 Why Base Plate Selection Matters In a chromium carbide overlay wear plate, the overlay layer provides extreme abrasion resistance, but the base plate is the backbone that carries structural loads, absorbs impact, ...Read more -

Which Hardness Test is Best for Wear Plates: Brinell, Rockwell, or Vickers?

Which Hardness Test is Best for Wear Plates: Brinell, Rockwell, or Vickers? In abrasive environments where wear plates are deployed — such as mining chutes, steel mill hoppers, or cement plant liners — hardness isn’t just a number. For a chromium carbide overlay wear plate or a bimetallic wear ...Read more -

Bimetallic Wear Plate vs. NM400: What’s the Difference and Which One to Choose?

Bimetallic Wear Plate vs. NM400: What’s the Difference and Which One to Choose? In industries where abrasion is a constant threat—mining, cement, steel, bulk handling—choosing the right wear plate is critical. Among the most commonly considered options are NM400 and bimetallic chromium carbide o...Read more -

Flatness Issues in CCO Plates: Causes & Fixes

Flatness Issues in CCO Plates: Causes & Fixes For customers who attempt to process composite wear-resistant steel plates on their own, plate flatness becomes a critical factor. Whether during storage, transportation, or cutting, any warping or unevenness in the plate can lead to serious prod...Read more -

From HRC to HV: How to Convert and Interpret Hardness Values in Chromium Carbide Overlay Plates

From HRC to HV: How to Convert and Interpret Hardness Values in Chromium Carbide Overlay Plates When it comes to evaluating the performance of a chromium carbide overlay wear plate, hardness is one of the most critical indicators. Yet across global markets, different testing methods and me...Read more -

What Is Chromium Carbide Overlay Wear Plate and Why Is It More Wear-Resistant Than Regular Steel?

What Is Chromium Carbide Overlay Wear Plate and Why Is It More Wear-Resistant Than Regular Steel? In heavy industries such as mining, cement, and power generation, equipment wear is a significant challenge. Regular steel components often suffer from rapid abrasion, resulting in frequent downtime ...Read more -

Inside the Manufacturing Process of Flux Cored Wire: Key Problems and Proven Fixes

Inside the Manufacturing Process of Flux Cored Wire: Key Problems and Proven Fixes The Rise of Flux Core Welding Wire In recent years, flux core welding wire has emerged as a preferred choice across industries such as shipbuilding, steel structures, mining, and heavy equipment manufacturin...Read more -

Plasma Cutting vs. Laser Cutting: Which Is Better for Wear Plate Processing?

Plasma Cutting vs. Laser Cutting: Which Is Better for Wear Plate Processing? In the realm of industrial manufacturing, CCO wear plates (Chromium Carbide Overlay) play a crucial role in extending the lifespan of equipment operating under high abrasion and impact conditions. These customized wear...Read more -

Global CCO Wear Plate Market Analysis: Who is Driving the Rise of High-End Wear Plates?

Global CCO Wear Plate Market Analysis: Who is Driving the Rise of High-End Wear Plates? Importance of wear-resistant plates in various industries CCO Wear Plate (composite wear-resistant steel plate) has been widely used in heavy industrial fields such as mining, metallurgy, electricity, and cons...Read more -

Key factors affecting the service life of CCO Wear Plate

Key factors affecting the service life of CCO Wear Plate In high-wear industries such as mining, steel smelting, cement manufacturing, and energy, CCO Wear Plate (cladding composite wear-resistant plate) is widely used in hoppers, conveying pipelines, liners, and other parts to resist strong wear...Read more -

What is the difference between wear plates and ordinary steel plates?

What is the difference between wear plates and ordinary steel plates? Steel plates, as one of the basic materials, play an indispensable role in the industrial manufacturing and heavy equipment industries. Different application environments have different requirements for steel plate performance,...Read more -

Overlay Wear Plate Processing and Customization Services

Overlay Wear Plate Processing and Customization Services In modern industrial production, CCO wear plate (chromium carbide overlay wear-resistant plate) is widely used in high-wear environments such as mining, building materials, steel, and electricity due to its excellent wear resistance and div...Read more -

Methods for Processing Wear-Resistant Steel Plates

Methods for Processing Wear-Resistant Steel Plates Due to its excellent wear resistance, wear-resistant steel plates are widely used in industries such as mining, power stations, and the cement industry. Its high strength and hardness enable the material to maintain good durability under harsh wo...Read more -

What is Flux Core Welding Wire

What is Flux Core Welding Wire Flux core welding wire is a type of consumable electrode used in welding processes, specifically designed for both self-shielded and gas-shielded applications. This welding wire is characterized by its tubular structure, which contains a core of flux material that ...Read more