In the highly competitive and demanding industrial world, the performance of wear – resistant products can be a game – changer for businesses. Tianjin Wodon Wear – Resistant New Materials Co., Ltd. has emerged as a leader, offering a revolutionary solution in the form of its high – impact wear plate. This product is not just another addition to the market; it’s a paradigm shift in how industries approach wear and tear issues.

Unrivaled Performance Features

Exceptional Impact Resistance

Tianjin Wodon’s high – impact wear plate is engineered to withstand the most punishing impacts. Using a unique combination of high – strength alloys and advanced manufacturing techniques, the plate can absorb and disperse impact energy effectively. When industrial equipment encounters sudden and powerful shocks, such as in mining operations where rocks are being blasted or in construction when heavy machinery is at work, this wear plate ensures that the underlying components remain intact. It can endure impacts that would quickly damage traditional wear – resistant materials, reducing the risk of equipment failure and costly downtime.

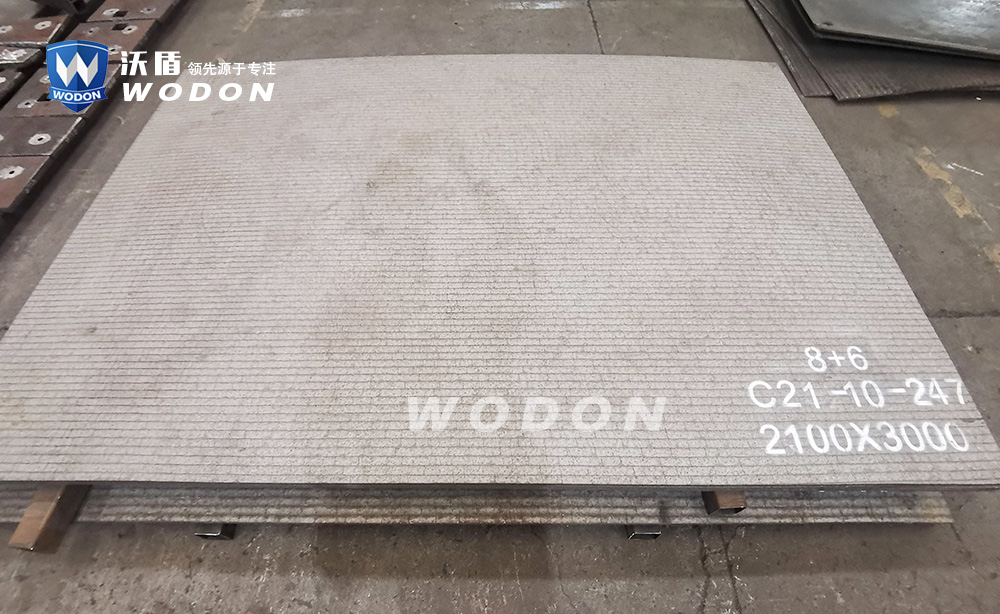

Superior Abrasion Resistance

Abrasion is a constant challenge in industries where materials are constantly in contact with abrasive substances. Wodon’s high – impact wear plate excels in this area. Its surface is designed with a special texture and composition that resists scratching, gouging, and erosion from abrasive particles. Whether it’s the rough ores in mining, the sharp aggregates in construction, or the abrasive powders in manufacturing, the wear plate can maintain its integrity over an extended period. This means longer – lasting equipment and fewer replacements, resulting in significant cost savings for businesses.

Outstanding Durability

Built to last, the high – impact wear plate from Tianjin Wodon combines the best of impact and abrasion resistance to offer exceptional durability. It can withstand the test of time even in the harshest working conditions, including extreme temperatures, high humidity, and corrosive environments. This durability is not only a testament to the quality of the materials used but also to the meticulous engineering and quality control processes employed by Wodon.

Diverse Applications

Mining Industry

In the mining sector, the high – impact wear plate is a crucial component. It is used in conveyor belts to protect against the constant abrasion from heavy ores and rocks. Crusher linings made from this wear plate can endure the high – impact forces generated during the crushing process. Bucket teeth on excavators and loaders are also often made with Wodon’s wear plate, allowing them to dig and scoop with greater efficiency and longevity.

Construction Industry

Construction equipment, such as bulldozers, backhoes, and dump trucks, are constantly exposed to abrasive materials and high – impact forces. Wodon’s high – impact wear plate is used to line the buckets, blades, and chutes of these machines. This not only extends the lifespan of the equipment but also improves its performance. For example, in road construction, where asphalt and gravel are being handled, the wear plate ensures that the equipment can operate smoothly without frequent breakdowns.

Manufacturing Industry

In manufacturing plants, especially those involved in the production of heavy – duty machinery or processing abrasive materials, the high – impact wear plate plays a vital role. It can be used to protect the internal components of machinery, such as the rollers in rolling mills or the impellers in pumps. By reducing wear and tear, it helps to maintain the precision and efficiency of the manufacturing process.

The Wodon Edge: R & D and Quality Assurance

Tianjin Wodon Wear – Resistant New Materials Co., Ltd. owes its success in producing such a high – quality product to its strong focus on research and development. The company has a team of experienced material scientists and engineers who are constantly exploring new materials and manufacturing techniques. They work closely with international research institutions and universities to stay at the forefront of wear – resistant material technology.

Moreover, Wodon has a strict quality assurance system in place. Every high – impact wear plate undergoes rigorous testing for impact resistance, abrasion resistance, and durability before leaving the factory. This ensures that customers receive a product that meets and exceeds industry standards.

If you’re looking for a reliable solution to your industrial wear problems, look no further than Tianjin Wodon’s high – impact wear plate. Contact us today to learn more about how our product can transform your operations and drive your business forward.

Post time: Feb-10-2025