Popular Design for Wear Elbow - WD1600 Wear Plates – Wodon

Popular Design for Wear Elbow - WD1600 Wear Plates – Wodon Detail:

WD1600 series

Abrasion Resistant Chromium Carbide Overlay

WD1600 is chromium carbide composite cladding fusion bonded to a mild steel backing plate. The deposit has been realized by means of submerged arc welding. WD1600 wear plate is suitable for application involving high abrasion and medium to high impact.

● WD1600 series:

Impact resistant wear plates; Suited for applications involving high abrasion and medium to high impact.

|

Chemicals |

Hardness |

Sheet Size |

Base Metal |

|

C – Cr – Nb – Mo – Fe |

HRC 58-63 |

1400*3500/2100*3500 |

Q235/Q345. etc |

| Chemical Composition(%) |

C |

Cr |

Mn |

Si |

Mo+Nb+V |

Fe |

|

3.0-6.0 |

25.0-45.0 |

1.0-3.0 |

1.0-3.0 |

* |

Bal. |

|

| Hardness |

HRC 58-65 |

|||||

| Standard Thickness(mm) |

4+4; 5+5; 6+4; 6+6; 8+6; 8+8; 10+6; 10+8; 10+10; 12+12; 12+17; etc (overlay thickness up to 32mm) |

|||||

| Standard Sheet Size(mm) |

1400*3500; 2100*3500; (Customized size available) |

|||||

| ASTM G65 Procedure A |

0.09 - 0.16g |

|||||

| Operating Temperature |

<600 ℃ |

|||||

| Base Metal Material |

Q235B, Q345B; A36; S235JR and structural steels |

|||||

| Main Industry |

Mining, glass industry, cement plant, steel mill, power plant, etc |

|||||

| Fabrication |

Plasma cutting, Gouging, Countersunk, stud bolt, Bending |

|||||

Note:Carbon and Chromium content varies in different plate.

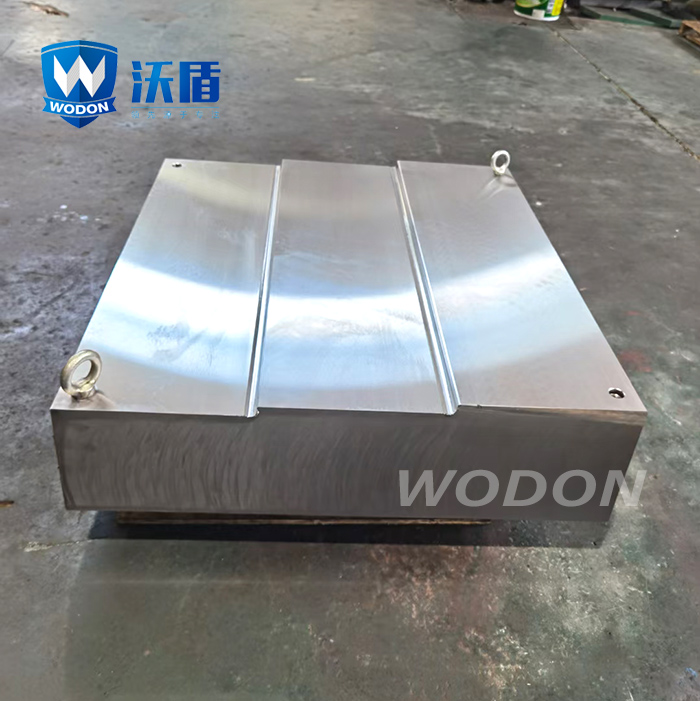

Product detail pictures:

Related Product Guide:

Well-run equipment, expert income workforce, and far better after-sales expert services; We are also a unified large family, anyone stick to the corporate value "unification, dedication, tolerance" for Popular Design for Wear Elbow - WD1600 Wear Plates – Wodon , The product will supply to all over the world, such as: Malta, Brasilia, Berlin, Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. We are looking forward to cooperating with friends from all over the world.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!