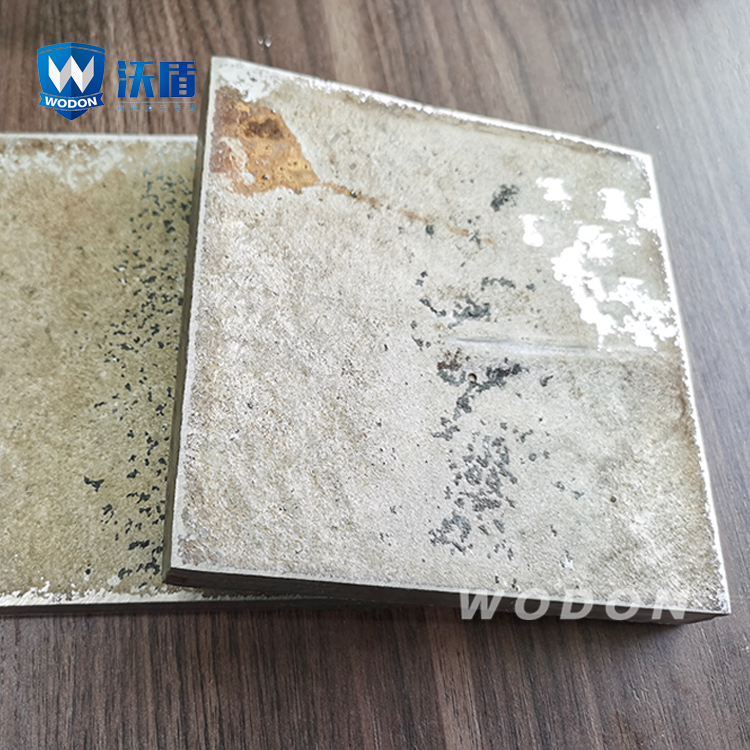

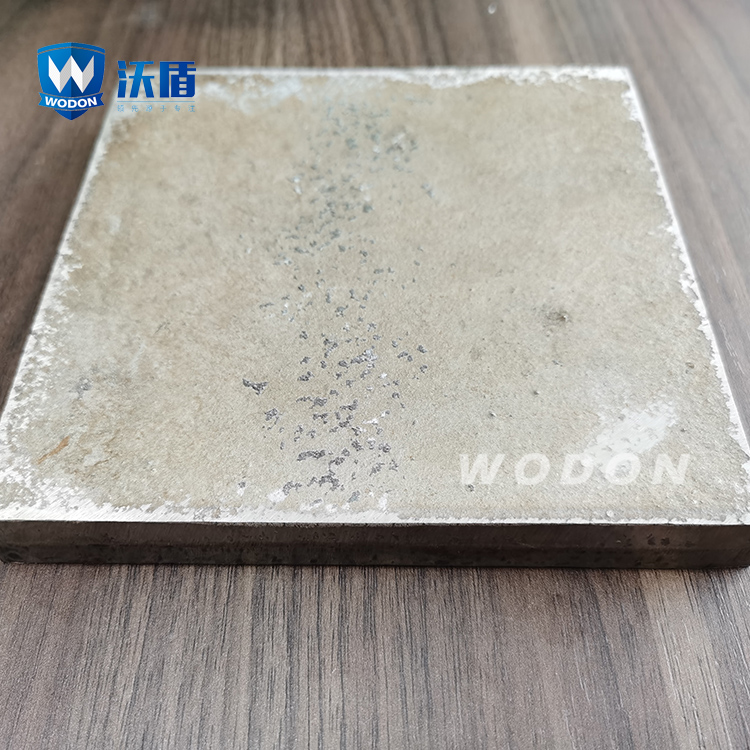

WD-M3 Smooth surface

Smooth Surface

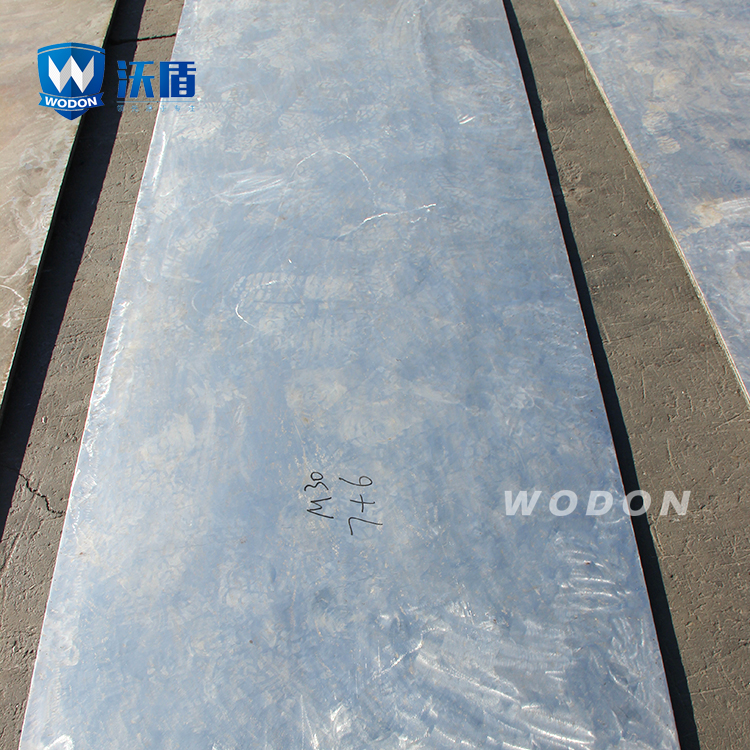

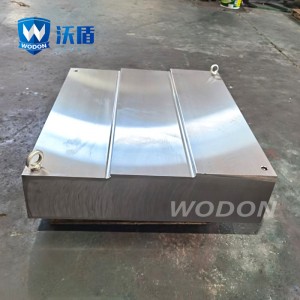

Chromium Carbide Overlay Plate

ADVANTAGE:

* Smooth surface, single pass overlay, No surface weld beads

* Consistent microstructure and hardness down to fusion line

* Low friction co-efficient

* Excellent abrasion and impact resistant properties

* Operating temperature <600℃

* Optional in unique non-magnetic overlay

* Available in mill and pre-polished surface finish

TYPICAL TECHNICAL STANDARD

|

Grade |

Chemical composition |

|||||||

|

|

C |

Cr |

Mn |

Si |

B |

S |

P |

Nb+Mo+Ti+V+W |

|

WD-M3 |

2.0-5.0 |

18-35 |

<1.5 |

<1.2 |

<0.6 |

<0.033 |

<0.033 |

<1.5 |

|

WD-M7 |

2.0-5.0 |

18-28 |

<1.5 |

<1.2 |

<0.4 |

<0.033 |

<0.033 |

7-10 |

| Basic Elements |

WD-M3 |

WD-M7 |

| Base material |

Q235B |

Q235B |

| Main alloy hard phase |

Chromium carbide |

Chromium carbide + Composite carbide |

| Primary carbide volume (%) |

>37 |

>37 |

| Overlay Hardness by HV (HRC) |

670 (58) |

670 (58) |

| Rubber weheel abrasion test with dry sand (g) |

<0.15g |

<0.14g |

| Impact abrasion test (g) |

<0.10g |

<0.08g |

| Standard thickness (mm) |

5/5, 6/7, 8/9, 10/11, 12/11, 17/11 |

17/11, 20/11, 24/13 |

| Standard plate size (mm) |

1000*3000, 600*3000 |

600*3000 |

| Recommended application |

Common abrasion |

Extreme abrasion |